PRODUCTS

01

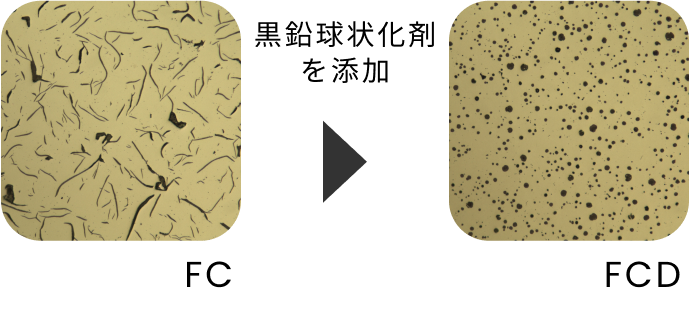

Globurizing Additives

Ductile cast iron is produced by adding Globurizing Additivess to molten cast iron. It is a type of cast iron in which graphite crystallizes into spheroids, and has excellent strength and elongation. From our diverse lineup, we will propose products that meet the needs of our customers.

New-CR Series

Compared to general Globurizing Additives, it is expected to reduce hydrogen gas pinholes, chill, slag inclusion, and shrinkage cavities.

NCLD-5

A Globurizing Additives that prevents the generation of chunky graphite.

Recommended for use on thick or large items that are prone to chunky graphite.

NCV-3

Globurizing Additives for CV cast iron.

CV processing can be easily performed using the pour-in method.

02

Inoculants

Adding an Inoculants to molten cast iron has the effect of preventing chill generation, improving graphite shape, stabilizing the base structure, and improving mechanical properties. From our diverse lineup, we propose products that meet the needs of our customers.

PRECALLOY Series

Induction furnace Pre Inoculants.

In addition to Si and C, trace amounts of O, S, Ca, Ba, Zr, Mn, RE and other active elements act to impart graphitization ability to the molten cast iron.

Barium Silicon Series

Ca-Ba-based all-purpose Inoculants.

Due to the high concentration of Ba and Ca, the duration of inoculation is long while reducing pinhole defects.(anti-fading effect).

Super Silist Series

Sr-based Inoculants for FC. Compared to general Inoculants, it is highly effective in reducing chill, internal shrinkage, pinholes and dross defects.

Zircasil Series

Zr-based Inoculants for ductile cast iron.

A highly functional Inoculants that not only supplies graphite nuclei like conventional Inoculants, but also refines dendrite cells and deoxidizes the molten cast iron.

New-Calloy Series

Ca-Si Inoculants for high strength materials

Especially in FC, it has the effect of improving graphite shape, increasing tensile strength, and densifying the cutting surface. It is suitable for FC300~350.

03

Other Additives

Carburizing materials Series

Carburizing materials for different purposes.

We have high and low nitrogen carburizing materials, so you can use them according to your purpose.

CryGra

Crystal graphite for rapid carburization.

This is crystalline graphite with a graphite-type crystal structure.

It has excellent penetration due to its crystal structure similar to that of graphite in molten cast iron and flux treatment to improve wettability.

S Pula

Iron sulfide for sulfur addition.

It allows to add sulfur stably to the molten cast iron.

Ecopara

Sn additive for improving hardness.

High-purity Sn (99.9% purity) shot.

It has the effect of turning the base structure of both FC and ductile cast iron into pearlite, increasing hardness.

Pararich A

As for FC, it has the effect of pearlizing the base structure and increasing the hardness stably.

As for ductile cast iron, a very small amount of addition has the effect of preventing chunky graphite.

Copper Nugget

Copper additive with 99.96% purity.

High-purity copper derived from copper wire scraps.

Copper Tablet

Powder compression press molded copper additive. Because it is in powder form, it can be added without leaving any residue.

NA Ferrophosphorus

Phosphorus additive.

Compared to conventional ferrophosphorus, this product has a lower impurity content and can be used with peace of mind.

NA-Ti

Titanium additive.

It fixes and neutralizes nitrogen gas in the molten cast iron, preventing nitrogen gas defects.

Cored Wire

A wire-shaped product in which various additives are coated with a thin steel plate.

It can enhance product yields by inserting it deep into the molten cast iron to add additive.

Cover material series for spheroidizing treatment

We have a wide range of products, including Fe-based, Fe-Si-based, and ceramic-based, and we will propose the most suitable product for your application.

MF Series

Mg-containing flux treatment with various alloying element additives.

Flux treatment provides good wettability and excellent diffusibility in molten cast iron.

Alloying element lineup: P, B, Ni, Cr, Mo, Mn, V, Ti, C

Others

We also carry a variety of alloy additives, ferroalloys, and ingots.

Please feel free to contact us.